Tin bar

SIGMA EB/T&FCT SN100C series tin bars are processed by vacuum continuous casting. This method removes pollutants to varying degrees and reduces the oxygen content of the solder bars. As a result, products with higher purity and less tin slag are obtained, which improves the welding performance. Quality, reduce defects.

SIGMA EB/T&FCT SN100C series tin bars are processed by vacuum continuous casting. This method removes pollutants to varying degrees and reduces the oxygen content of the solder bars. As a result, products with higher purity and less tin slag are obtained, which improves the welding performance. Quality, reduce defects.

Our advantage:

* Smelted from high-purity refined tin

* Oxides, less dross

* Small surface tension

* Fast packaging, good wettability

| Alloy Number |

Alloy composition |

Melting point |

Features |

Download |

Remarks |

|

EB993A |

Sn-0.7Cu |

227 |

Medium temperature soldering, low cost, suitable for common dip and wave soldering processes. |

|

|

|

EB965A |

Sn96.5-Ag3.0-Cu0.5 |

217-219 |

Medium temperature solder, suitable for high-end dip and wave soldering processes. Excellent electrical conductivity, good through-hole climb, good mechanical properties |

|

|

|

T100 |

Sn-0.7Cu+ |

227 |

Medium temperature solder, the choice to replace high silver solder. |

|

|

|

SN100C® |

Sn-0.7Cu-0.05Ni+0.01Ge |

227 |

Medium temperature solder, low corrosion and good wettability, it is the standard alloy of tin, copper and nickel in the industry. |

|

Under license from FCT Asia and Nihon Superior |

|

SN100CL |

Sn-0.7Cu-0.05Ni+0.01Ge |

227 |

Medium temperature solder, low corrosion and good wettability, it is the standard alloy of tin, copper and nickel in the industry. It is suitable for hot air leveling process. |

|

|

|

For more alloy formulas, please contact our company. |

|||||

SN100C® Lead-Free Solder Superior Reliability Alloy

SN100C® Lead-Free Solder Superior Reliability Alloy

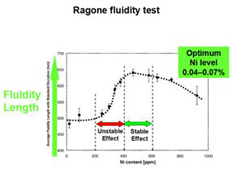

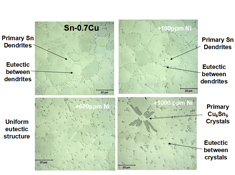

SIGMA and FCT ASIA of the United States have signed an agreement to jointly manufacture an alloy of SN100C solder based on the relevant patents of NIHON SUPERIOR. SN100C is equipped with a small amount of nickel in Sn-Cu solder, which has completely different characteristics from Sn-Cu solder. The melting point of SN100C is the same as that of Sn-Cu eutectic solder, which is 227 °C, but due to the effect of nickel, the solder has good fluidity when molten, and the surface of the solder when solidified is smooth and shiny, with few cracks. The tensile test can show high elongation, relieve various stresses, and is also excellent in impact resistance and vibration resistance. It is able to cope with and improve many problems found in other lead-free solders, and the results of adoption by many manufacturers are improving.

Feature points for superior welding characteristics.

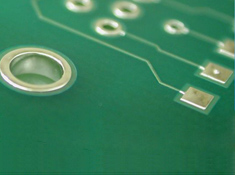

① The welding surface is bright, shiny, and climbs well.

② Good solder fluidity, less solder bridges, and lower defect rate.

③ The alloy layer of the bonding interface is stable and reliable, and has excellent thermal cycle resistance.

④ Due to the effect of nickel, copper corrosion is less.

⑤ The sound quality becomes better. (Thanks to the support of audio manufacturers and enthusiasts)

SN100CL(HASL) Hot Air Leveling PCB Surface Treatment Best Choice

SN100CL hot air leveling occupies the primary position of PCB surface treatment alloy in the lead-free era; adding a small amount of nickel inhibits the growth of intermetallic compounds, stabilizes the IMC layer, and improves the fluidity of solder; the addition of germanium and Ge inhibits multiple reflows No yellowing, good antioxidant capacity.

SN100CL product features:

* Stable alloy layer

* Smooth and bright surface, uniform tin thickness

* Inhibit copper corrosion

* Repeated reflux without yellowing

|

|

|

|

Contact information

Contact us

Dongguan Xingma Soldering Co., Ltd.

Building 3, Guanghui Industrial Zone B, Dongcheng Science and Technology Park, Bayi Road, Dongcheng District, Dongguan City

TEL:0769-27382189

FAX:0769-27384958

Contact:Mr. Du13686663819

E-mail:sm@sigmasolder.com

http://www.sigmasolder.com

COPYRIGHT © 2021 Dongguan Xingma Soldering Co., Ltd. 粤ICP备12010865号 Powered by www.300.cn